To produce gummed, closed and folded booklets, two machines are needed:

A TD6 press to print stamps

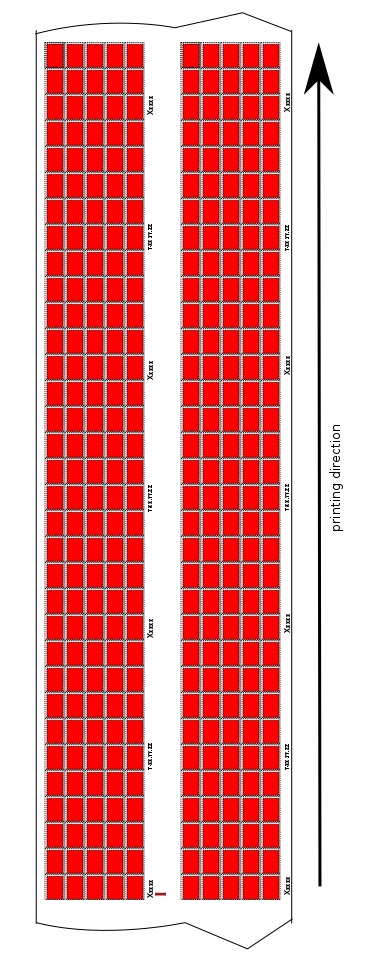

- printing scheme for booklets on a TD6 press

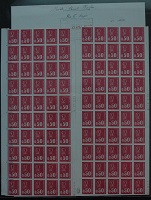

There are two main differences for the use of such a press compared to the production of sheets of stamps: each cylinder turn prints 330 stamps in the form of two blocks of five columns (33 rows of 10 stamps with a central gutter) and the delivery of stamps is made through two rolls with a width of five stamps after cutting the endless strip of stamps. Printer’s markings (control number, plate number and date) are printed on the right and on the central gutter of the sheets every ten booklets. The electronic mark is printed on the central gutter every 33 booklets.

It is now possible to define the notion of “aristo” booklet: it is a booklet which possesses an electronic mark (generally straddling the upper and lower pane because the guillotining of the endless strip of stamps is supposed to cut the mark) and a date on its right margin.

With the indications given above on the printing process (and Bézout’s theorem), it may be shown that there is one “aristo” booklet every 330 booklets for closed booklets of 10 stamps and one “aristo” booklet every 165 booklets for closed booklets of 20 stamps.

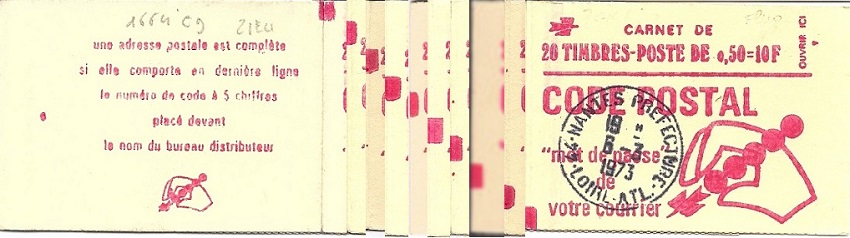

- cover of the C2 booklet produced by the packaging machine number 6

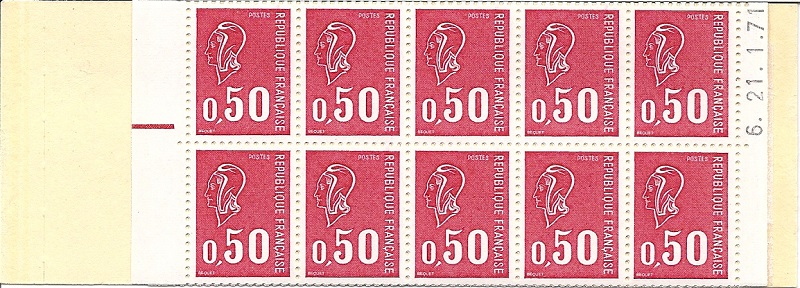

- the upper pane of the above booklet: it is an "aristo" booklet made on the press TD6-6 on 21.1.71 with the electronic mark number 2

- the lower pane of the above booklet (the end of the electronic mark can be seen on the right)

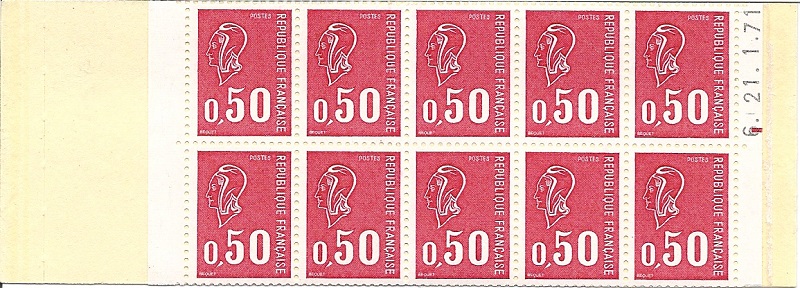

- reconstitution of the sheet of the above booklet showing the complete electronic mark

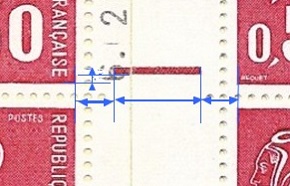

- characterization of the electronic mark of a booklet

Thanks to the opposite image, we may recall how the electronic mark of a booklet is characterized. The following parameters are measured (in millimetres):

- The length of the electronic mark;

- The distance between the base of the electronic mark and the base of the nearby stamp;

- The distance between the left edge of the electronic mark and the stamp to the left;

- The distance between the right edge of the electronic mark and the stamp to the right.

Thus, the electronic mark of the sleeve number 2 has the following parameters, according to the brochure “Les carnets du 0,50 Marianne de Béquet” by J. RENARD:

length = 9,9; left distance = 4,1; distance to the base = 1,1; right distance = 4,0.

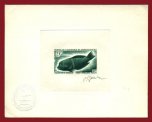

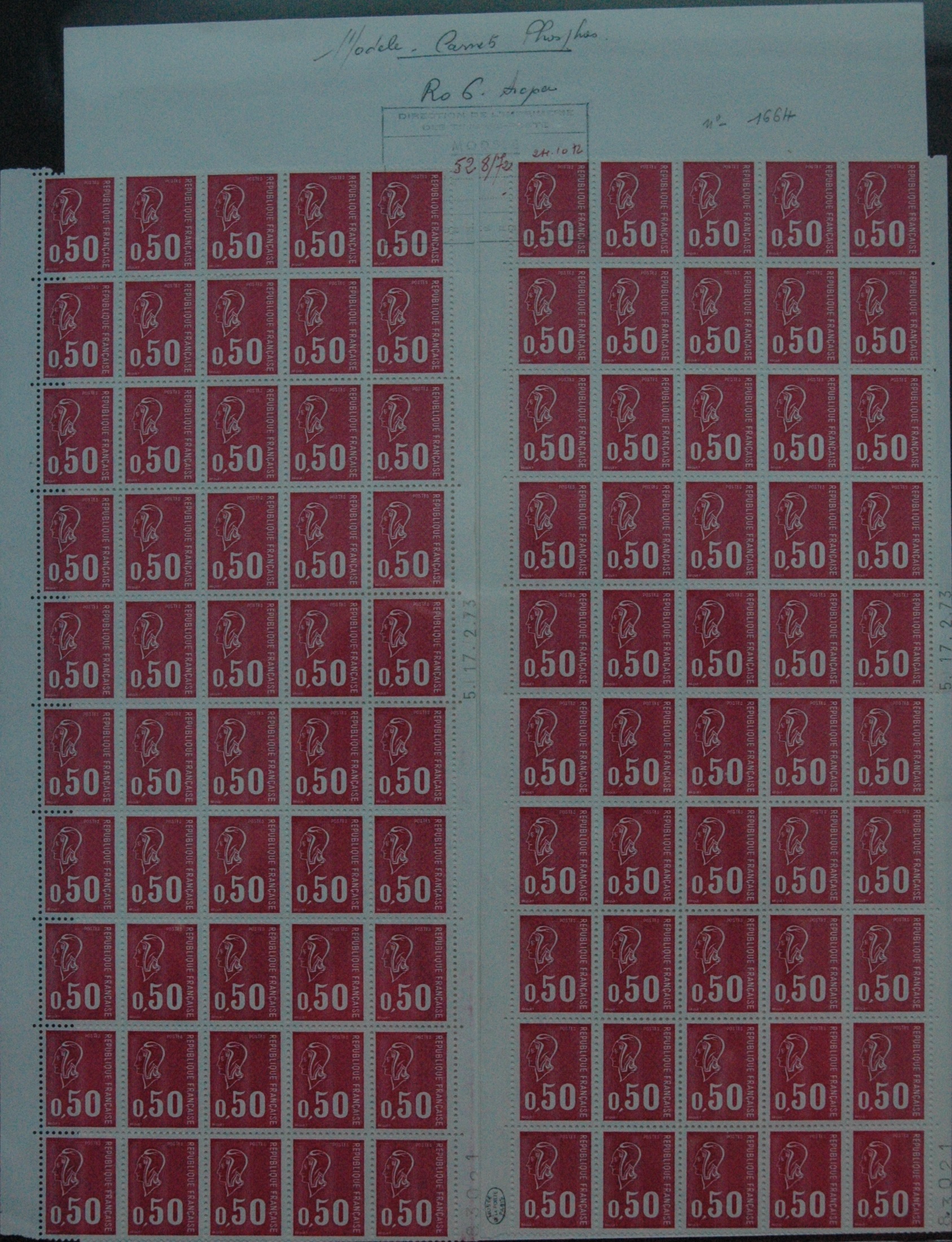

Shown below is an imprimatur sheet for the preparation of booklets with the stamp 0,50F Marianne de Béquet visible at the French Postal Museum:

- imprimatur sheet for the making of booklets ( Copyright Coll. L’Adresse Musée de La Poste, Paris / La Poste)

A packaging machine to print covers and make booklets

Covers are flexo-printed with rubber printing plates, aniline ink and two cylinders:

- a cylinder for the wording of covers with a diameter of 41,4 mm for the booklets of 10 stamps or 82,8 mm for the booklets of 20 stamps;

- a cylinder for counting marks with the same diameter as the cylinder for wording (counting marks allow to see at a glance if a booklet is missing). A bar system on the impression cylinder allows a progressive lag in order to obtain nine marks on 260 mm. The 9 th mark being bigger is cut in two to achieve ten marks. Here is an illustration of these marks on the following two pictures:

- a series of 10 C7 type booklets of the stamp 0,50F Marianne de Béquet showing the growing gap between the 10 marks allowing an easy counting

- a series of 10 C9 type booklets of the stamp 0,50F Marianne de Béquet showing the growing gap between the 10 marks allowing an easy counting

The running principle of a packaging machine is as follows: this machine drives three strips of paper (two for stamps and one for covers) at the same scrolling speed to make them coincide when cutting the booklet. An electronic system regulates ahead of or behind three differentials to bring into line the speed of the cover, the correspondence of the two strips of stamps and the cut of the booklet at the perforation location, after an optical reading of perforation.

The sticking of booklets is made by applying a plastic industrial glue with a grooved roulette which applies three stripes of adhesive to fix the two strips of stamps on the cover and to close the booklet.

Eight packaging machines were used for the printing of booklets with the stamp 0,50F Marianne de Béquet:

- The packaging machines 1 and 2: they had a different design than the six other machines and were difficult to control. Transferred to Boulazac, they were abandoned after a last test with the closed booklet of 5 stamps 0,80F red Marianne de Béquet.

- The packaging machines 3 to 8: they could produce approximately 70000 booklets a day.

Site map

Site map

Contact

Contact

Legal notices

Legal notices

Editors area

Editors area

2015-2017 © Etude monographique du 0,50F Marianne de Béquet - All rights reserved

Home

Home